PENELOPE

Programme: H2020

Topic: DT-FOF-10-2020 Pilot lines for large-part high-precision manufacturing

Project Coordinator: AIMEN – Asociacion de Investigacion Metalurgica del Noroeste (SPA)

Start year: 2020

EU Website: https://cordis.europa.eu/project/id/958303

Project website: https://penelope-project.eu/

Description

Context

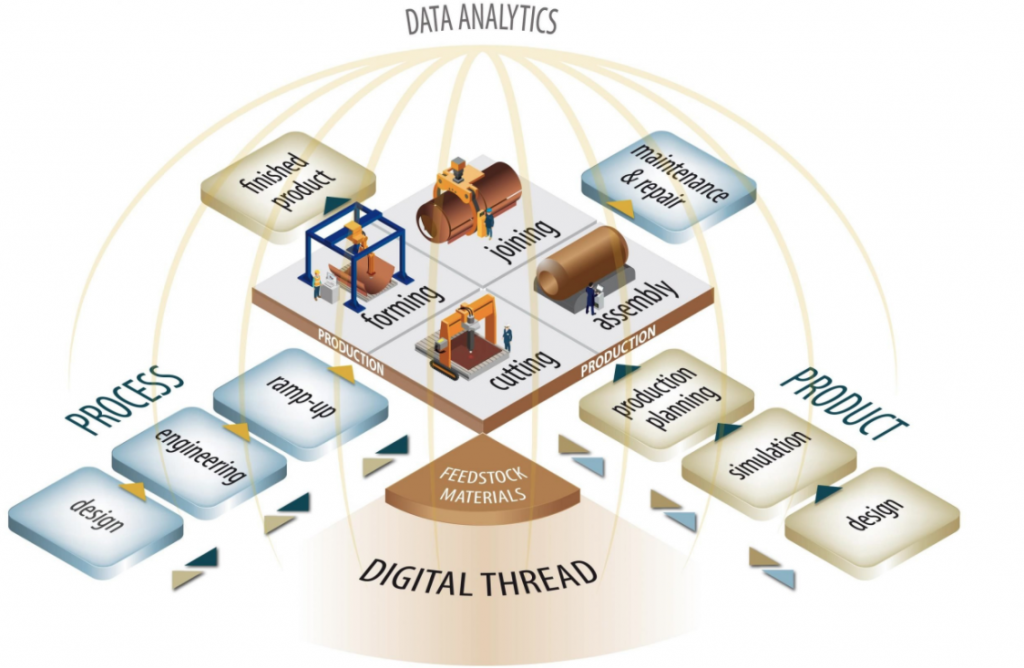

The manufacturing of large-scale parts needs the implementation of a holistic data management and integrated automation methodology to achieve the desired levels of precision using modular and more flexible equipment.

Large-part manufacturing is characterized by the high customization required (built-customer specific). Also, manufacturing of complex large-scale parts involves a variety of subassemblies that must be manufactured and assembled. This high degree of personalization implies a great effort in the design and the posterior verification after manufacturing, to achieve high precision. On the other hand, this customised product-centric design requires an optimisation of the resources of the workshop –i.e. workers, machines, devices— for a responsive, reconfigurable and modular production, targeting the execution of key labour-intensive tasks by preserving industry-specific workers’ knowledge and skills (worker-centric approach).

Project

PENELOPE proposes a novel methodology linking product-centric data management and production planning and scheduling in a closed-loop digital pipeline for ensuring an accurate and precise manufacturability from the initial product design. PENELOPE is built over five pillars for developing a common methodology and vision deployed in four industrial-driven pilot lines in strategic manufacturing sectors (Oil&Gas, Shipbuilding, Aeronautics and Bus&Coach) and with potential replicability to other sectors. Moreover, it will be set a pan-European network of Didactic Factories and showrooms, providing training and upskilling capabilities enabling the workforce transition towards Industry 4.0 and general-purpose testbeds for assisting in the industry adoption. PENELOPE envision to highly-increase EU manufacturing sector competitiveness by increasing production performance, quality and accuracy while ensuring workers’ safety and resource efficiency.

XiLAB defined novel UX tools and developed intelligent manufacturing digital twins for some uses cases in the project.

Related publications

Bilancia, P., Monari, L., Raffaeli, R., Peruzzini & M., Pellicciari, M. (2022) Accurate Transmission Performance Evaluation of Servo-Mechanisms for Robots, Robotics and Computer-Integrated Manufacturing, Vol. 78, 102400

Khamaisi, R. K., Brunzini, A., Grandi, F., Peruzzini, M.;,Pellicciari, M. (2022) UX assessment strategy to identify potential stressful conditions for workers, Robotics and Computer-Integrated Manufacturing, Vol. 78, 102403

Khamaisi, R. K., Grandi, F., Prati, E., Peruzzini, M., Pellicciari, M. (2022) A comprehensive UX index to evaluate industrial tasks from a human-centered perspective, in 2022 IEEE International Conference on Metrology for Extended Reality, Artificial Intelligence and Neural Engineering (MetroXRAINE), Rome 26-28 October 2022, https://doi.org/10.1109/MetroXRAINE54828.2022.9967677

Raffaeli, R., Bilancia, P., Neri, F., Peruzzini, M. & Pellicciari, M. (2022) Engineering Method and Tool for the Complete Virtual Commissioning of Robotic Cells, Applied Sciences, Vol. 12(6), 3164

Ferrarini, S., Bilancia, P., Raffaeli, R., Peruzzini, M., Pellicciari, M. (2024) A method for the assessment and compensation of positioning errors in industrial robots,

Robotics and Computer-Integrated Manufacturing, Vol.85, 102622